adannaaollinsowenn

Member

- Se incorporó

- 13 Octubre 2023

- Mensajes

- 19

- Reaction score

- 0

- Puntos

- 6

- Edad

- 39

Nails are ubiquitous fasteners used in various construction and woodworking projects. They come in different types and sizes, each designed for specific applications. In this blog post, we will delve into three types of nails: wire collated nails, 15-degree siding nails, and 3-inch coil nails. We will explore their features, applications, and benefits, providing insights into their usage in different industries. By understanding the characteristics and advantages of these nails, we can make informed choices when selecting the most suitable fasteners for our projects.

Wire collated nails are a type of nails that are held together by a thin wire strip or coil. These nails are commonly used in pneumatic nail guns to ensure efficient and rapid fastening. Key features and applications of wire collated nails include:

Collation Types: Wire collated nails are available in two primary collation types: plastic collation and paper collation. Plastic collated nails are more durable and less likely to break during handling and loading into nail guns. Paper collated nails are more environmentally friendly and can be easily recycled.

Versatility: Wire collated nails are versatile and can be used in various applications, including framing, sheathing, decking, and general construction. They provide reliable and secure fastening for a wide range of materials such as wood, plywood, and engineered lumber.

Efficiency: The wire collation system allows for rapid and continuous nail feed in pneumatic nail guns, improving productivity and reducing downtime. The collated nails are fed smoothly and consistently, minimizing the need for manual loading and enhancing workflow efficiency.

15-degree siding nails, also known as wire-coil nails, are specifically designed for siding and exterior trim applications. These nails are coil-shaped and are typically used with pneumatic coil nail guns. Key features and applications of 15-degree siding nails include:

Angled Design: 15-degree siding nails have an angled shank, typically ranging from 15 to 16 degrees. This angle allows for better access to tight spaces and corners, making them ideal for siding installation and exterior trim work.

Weather Resistance: 15-degree siding nails are often made from corrosion-resistant materials such as stainless steel or hot-dipped galvanized steel. This ensures their durability and resistance to the elements, making them suitable for outdoor applications.

Holding Power: The angled shank design and ring or helical thread patterns on 15-degree siding nails provide enhanced holding power. This helps prevent nail pull-through and ensures a secure and long-lasting installation, even in high-wind areas.

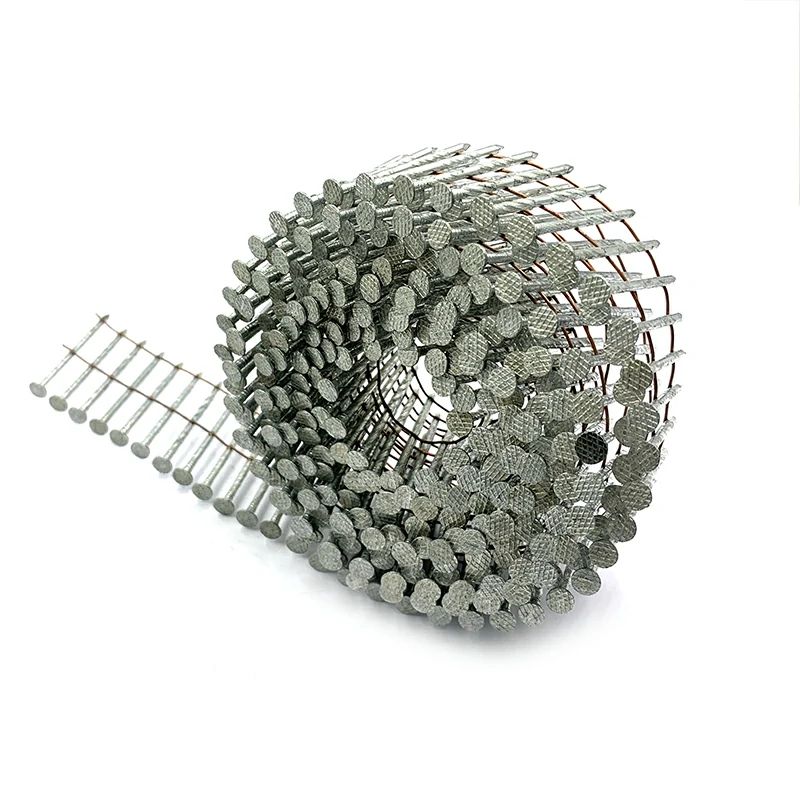

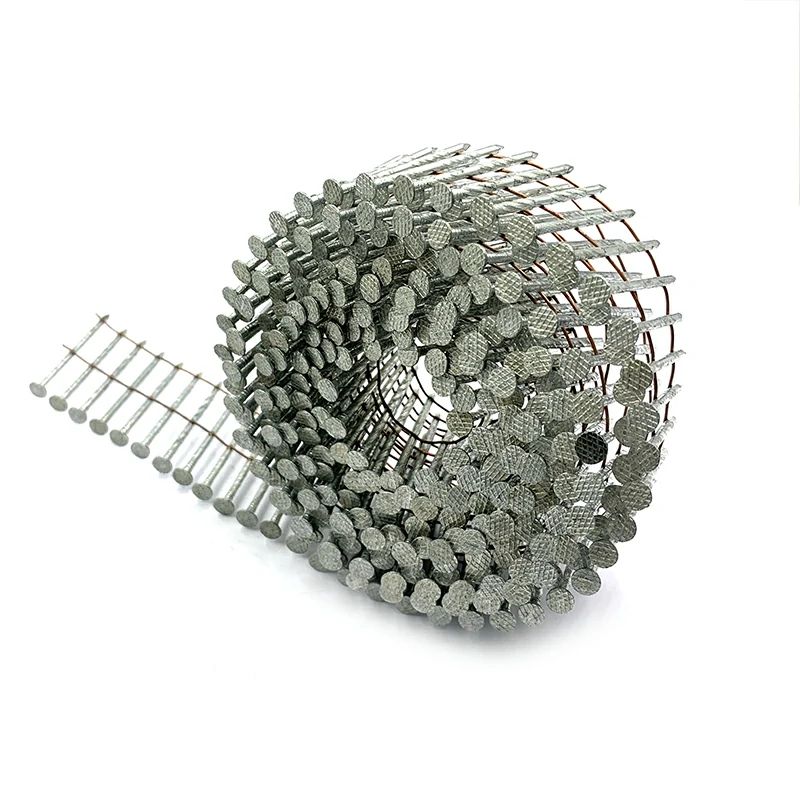

3-inch coil nails, also referred to as coil framing nails or coil nails, are longer nails used in heavy-duty framing and construction applications. These nails are held together in a coil shape and are compatible with pneumatic coil nail guns. Key features and applications of 3-inch coil nails include:

Length and Shank Design: 3-inch coil nails have a longer length, which makes them suitable for tasks that require deeper penetration, such as framing, decking, and structural applications. They typically have a smooth shank, providing a firm grip and minimizing withdrawal.

Durability and Strength: 3-inch coil nails are manufactured from strong materials like hardened steel, ensuring their durability and resistance to bending or breaking during installation. They can withstand the high impact and heavy loads associated with framing and construction work.

Efficient Installation: The coil shape of these nails allows for a large quantity of nails to be loaded into a pneumatic coil nail gun, reducing the frequency of reloading. This leads to increased productivity and less downtime on the job site.

Versatility: 3-inch coil nails can be used for a wide range of applications, including framing, sheathing, truss assembly, and general construction. They provide reliable fastening for lumber, engineered wood products, and other building materials.

Understanding Wire Collated Nails

Wire collated nails are a type of nails that are held together by a thin wire strip or coil. These nails are commonly used in pneumatic nail guns to ensure efficient and rapid fastening. Key features and applications of wire collated nails include:

Collation Types: Wire collated nails are available in two primary collation types: plastic collation and paper collation. Plastic collated nails are more durable and less likely to break during handling and loading into nail guns. Paper collated nails are more environmentally friendly and can be easily recycled.

Versatility: Wire collated nails are versatile and can be used in various applications, including framing, sheathing, decking, and general construction. They provide reliable and secure fastening for a wide range of materials such as wood, plywood, and engineered lumber.

Efficiency: The wire collation system allows for rapid and continuous nail feed in pneumatic nail guns, improving productivity and reducing downtime. The collated nails are fed smoothly and consistently, minimizing the need for manual loading and enhancing workflow efficiency.

Understanding 15-Degree Siding Nails

15-degree siding nails, also known as wire-coil nails, are specifically designed for siding and exterior trim applications. These nails are coil-shaped and are typically used with pneumatic coil nail guns. Key features and applications of 15-degree siding nails include:

Angled Design: 15-degree siding nails have an angled shank, typically ranging from 15 to 16 degrees. This angle allows for better access to tight spaces and corners, making them ideal for siding installation and exterior trim work.

Weather Resistance: 15-degree siding nails are often made from corrosion-resistant materials such as stainless steel or hot-dipped galvanized steel. This ensures their durability and resistance to the elements, making them suitable for outdoor applications.

Holding Power: The angled shank design and ring or helical thread patterns on 15-degree siding nails provide enhanced holding power. This helps prevent nail pull-through and ensures a secure and long-lasting installation, even in high-wind areas.

Understanding 3-Inch Coil Nails

3-inch coil nails, also referred to as coil framing nails or coil nails, are longer nails used in heavy-duty framing and construction applications. These nails are held together in a coil shape and are compatible with pneumatic coil nail guns. Key features and applications of 3-inch coil nails include:

Length and Shank Design: 3-inch coil nails have a longer length, which makes them suitable for tasks that require deeper penetration, such as framing, decking, and structural applications. They typically have a smooth shank, providing a firm grip and minimizing withdrawal.

Durability and Strength: 3-inch coil nails are manufactured from strong materials like hardened steel, ensuring their durability and resistance to bending or breaking during installation. They can withstand the high impact and heavy loads associated with framing and construction work.

Efficient Installation: The coil shape of these nails allows for a large quantity of nails to be loaded into a pneumatic coil nail gun, reducing the frequency of reloading. This leads to increased productivity and less downtime on the job site.

Versatility: 3-inch coil nails can be used for a wide range of applications, including framing, sheathing, truss assembly, and general construction. They provide reliable fastening for lumber, engineered wood products, and other building materials.